Green-Paq – Inflatable Packaging for Fragile Goods

Less Space and Fewer Logistics

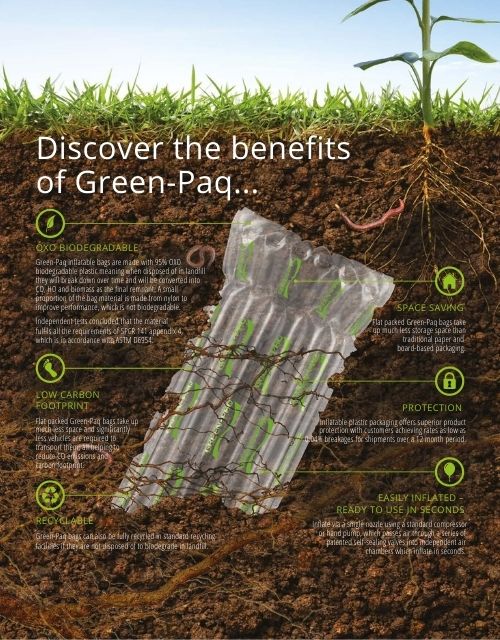

Uninflated bags take up much less space than paper and board-based protective packaging (for example there are an average of 10,000 Green-Paq deflated bags stored on just one euro-pallet), meaning significantly less vehicles are required to transport them and much less storage space is required, all helping to reduce CO2 emissions and carbon footprint.

This is an excellent packing solution for fragile items such as:

- Wines, beers & Spirits

- Mobile Phones

- iPads & Tablets

- Laptops & Monitors

- Cosmetics

Light Weight – Green-Paq

The weight of any packaging materials will directly impact the amount of energy required to transport both the packaging materials themselves and also the pack of finished goods to the retailer or end-user. Switching to a lighter weight material can positively impact your carbon footprint. Once inflated and ready for use, inflatable Green-Paq bags consist of only 2% plastic and 98% air – so, that’s pretty much as light as air!

Quiet/Small generator for inflating pouches

Biodegradable Green-Paq

Green-Paq inflatable bags are made with 95% OXO biodegradable plastic, meaning they start to degrade once disposed of in landfill.

The bags undergo a two-stage degradation process. The first is Oxidative Degradation enhanced by a catalytic reaction. Once this has happened the second part is biodegradation in soil or a bio-active composting environment. The OXO biodegradable material is converted into CO, HO and biomass as the final remnant. A 22 small proportion of the bag material is made from nylon to improve performance, which is not biodegradable.

The biodegradability of the Green-Paq material has been tested by the SP Technical Research Institute of Sweden (“SP”) who performed SP Method SPCR 141 Appendix 4 “Polymeric Waste degradable by abiotic and subsequent biological degradation (A + B Degradation)- Requirements and test Methods.” SP concluded that the test material fulfils all the requirements of SPCR 141 Appendix 4, which is in accordance with ASTM D6954.